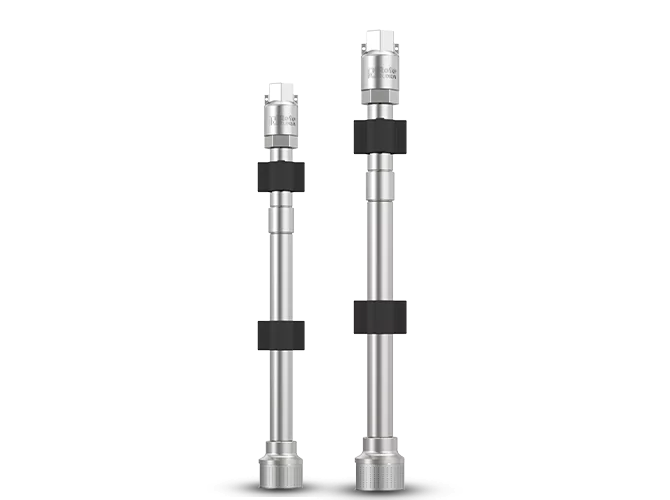

Introduction to Helical Rotor Submersible Pumps

Roto’s helical rotor submersible pumps are specifically designed for efficient handling of viscous fluids and liquids containing solids. These pumps are ideal for industries requiring consistent fluid transfer in challenging environments such as deep wells, wastewater treatment plants, and agricultural applications.

Key Features

Key features of Roto Helical Rotor Pumps include the ability to handle high-viscosity liquids, making them ideal for various industrial applications. Additionally, their high durability guarantees long-lasting performance, even under demanding conditions, making them a reliable choice for challenging pumping tasks.

Handles high-viscosity liquids

Submersible design

Low maintenance

High durability

Ideal for Complex Fluid Dynamics

Helical rotor submersible pumps are the perfect solution for industries that deal with complex fluid transfer, such as wastewater management and oil extraction. With their ability to handle a wide range of viscosities and solid content, these pumps maintain efficient operation even under fluctuating pressure conditions.

Applications Include:

Sewage management in wastewater

Offshore oil and gas extraction.

Agricultural irrigation and water transfer.

Cooling systems in power plants.

Advantages of Helical Rotor Submersible Pumps

With our innovative design, Roto Helical Rotor Pumps deliver exceptional performance across various applications. Their energy efficiency not only minimizes operational costs but also supports sustainability initiatives.

Energy-efficient operation, reducing costs.

Roto pumps offer energy efficiency, helping lower operational costs.

Capable of handling diverse fluid types.

Designed to handle a wide range of fluids with ease.

Durable construction for long-lasting use.

Built with durable materials for extended service life.

Low maintenance, minimizing downtime.

Requires minimal maintenance, reducing downtime and costs.

Specifications

At Roto Energy Systems, we offer customized helical rotor pump solutions tailored to meet the specific challenges of your industry. Whether it’s deep-well pumping, sludge management, or high-viscosity fluid handling, Roto’s helical rotor submersible pumps provide unmatched performance.

Technical Specifications

| Range: | 0.5 Hp to 3 Hp |

| Discharge: | 0.8 m3/h to 8 m3/h |

| Head Range: | 30 m to 300 m |

FAQs

What are helical rotor submersible pumps best suited for?

Helical rotor submersible pumps are ideal for handling high-viscosity fluids, liquids containing solid particles, and abrasive materials. They are commonly used in wastewater treatment, oil extraction, and agricultural irrigation.

How does the helical rotor design improve pump efficiency?

The helical rotor design ensures a smooth, low-pulsation flow, which reduces internal friction and wear. This makes the pump highly efficient for transferring viscous and solid-laden fluids with minimal energy consumption.

Can helical rotor submersible pumps operate at varying depths?

Yes, helical rotor submersible pumps are designed to operate effectively at different depths, maintaining steady flow and pressure in deep well or underwater applications.

What types of fluids can be handled by a helical rotor submersible pump?

These pumps can handle a wide range of fluids, including sludge, sewage, high-viscosity liquids, and fluids containing solids, making them versatile for various industries.

Are helical rotor submersible pumps energy-efficient?

Yes, these pumps are highly energy-efficient, especially when handling complex fluids. The design minimizes energy consumption while ensuring reliable performance in challenging environments.

What maintenance is required for helical rotor submersible pumps?

Helical rotor submersible pumps require minimal maintenance due to their robust design and wear-resistant materials. Regular inspections and cleaning are recommended to ensure optimal performance and longevity.